Advantages

Versatile throughout.

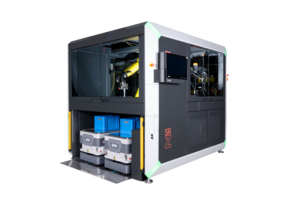

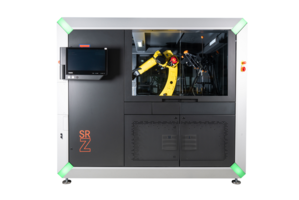

The SRZ is your integrated solution for fully automated production. With the flexible robot cell, you can combine a wide range of processing steps with minimal use of personnel - your universal support for both small and large batch sizes. Can be used as a stand-alone cell, in conjunction with up to two machine tools or as a link in a more extensive chain.

Features

Futuristic design.

Evolution of efficiency: The third generation of the SRZ stands out thanks to its further improved flexibility. The narrower frame creates more space for storage and process modules, for example for loading and unloading, checking and reworking, packing and palletizing. This not only looks futuristic, but also makes your automation reassuringly future-proof.

NOTE: The systems shown are sample configurations and applications that can be adapted in many ways to your own needs. If you have any further wishes or requirements, please contact us. We would be happy to develop an individual concept and offer for you. ► Send project request

Applications

24/7 with many functions.

The SRZ is recommended for fully automatic loading and unloading of connected machines as well as for stand-alone operation, for example for testing or assembly activities. The integration of upstream or downstream processes provides additional added value.

Possible handling objects:

Workpieces, clamping pallets and/or tools

Ideal batch size:

small to large

► Discover possible applications in your production

| Integrated robot(s) | 1-3 |

|---|---|

| Max. robot load | Approx. 70 kg |

| Robot makes | FANUC, KUKA or based on customer specifications |

| Possible machine connections | 1-2 |

| Data interfaces | PROFINET, PROFIBUS, PROFIsafe, Ethernet, Hardware, IO-Link, etc. |

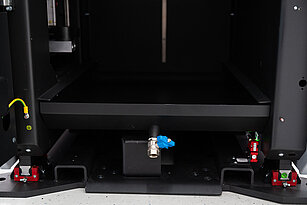

| Storage solutions | Various standard modules available (see storage modules) |

| Main time parallel equipping | Yes |

| Integration of additional process modules | Yes (see process modules) |

| Integration of HaTPad | Optional |

| Custom adjustments possible | Yes |

| Safety | Integrated cell concept with laminated safety glass and transponder coded safety switches |

Not exactly what you need?

Perhaps one of our other platforms would be a better match to your requirements.

Easier with the HaTPad

With the HaTPad, operating your system is as easy as ever. With intelligence and connectivity, it is also ready to tackle any Industry 4.0 challenge.

We are happy to consult you

Let us know the challenges you face in your production. We work with you to provide the right solutions and take care that they are implemented.