The HandlingTech Success Story

From the cold start in the basement of our parent company’s turned parts operation to a veritable player in the robotics industry. Since the beginning, innovation has been the motivation and basis of our success. Today, we can say with pride that we have put quite a bit in motion since 1994 and that we have become a market leader in the field of global automation.

25-year anniversary celebration

Together with prestigious partners, HandlingTech celebrates 25 years of automation during a special evening event.

What a team

Despite the fact that the production area is not increased in size and personnel setbacks, a strong increase in incoming orders and the success experienced in the implementation of the structuring measures, HT realizes enormous growth.

HandlingTech becomes a sponsoring partner for the Nordic combined athlete Manuel Faißt.

Assembly area: 3,500 m2

Employees: 81

Sales: EUR 17 million

Number of sold robot cells: 840

Automation Turbo

The HT Sales Center West in Werdohl is launched.

Planning begins for the first complete production line for an automotive customer with a hall floor space of 2,400 square meters, which is then delivered in 2018.

In this year, a total of 7 youngsters start their apprenticeship.

Assembly area: 3,500 m2

Employees: 79

Sales: EUR 12 million

Number of sold robot cells: 740

![[Translate to English:] Einführung der neuen palletZ für Palettenhandling und mehr auf der Automatica in München [Translate to English:] Einführung der neuen palletZ für Palettenhandling und mehr auf der Automatica in München](/fileadmin/_processed_/0/e/csm__KBF5919_45c2efae1e.jpg)

Introduction of palletZ

The modular and easily expandable palletZ for easy pallet handling is introduced for the first time at Automatica in Munich.

More departments are moved into the neighboring building and the first Kardex storage tower eases up the situation relating to the space problems.

The eromobil receives the German Design Award.

HandlingTech becomes a sponsoring partner for TVB 1898 Stuttgart.

Assembly area: 3,200 m2

Employees: 65

Sales: EUR 11.4 million

Number of sold robot cells: 641

20-year anniversary celebration

HandlingTech celebrates its 20-year anniversary.

The ecoZ receives the Red Dot Award and development of the HaTPad begins as a touch control element in times of digitization.

The company’s growth requires eromobil® and the conveyor belt be moved into the neighboring building of Hutzel DrehTech.

Assembly area: 3,200 m2

Employees: 67

Sales: EUR 11.5 million

Number of sold robot cells: 580

ecoZ wins an award

The Good Design Award is presented for the ecoZ and the product celebrates its introduction to the market.

The new product line eromobil® metal eroding unit with automatic feed is created.

A solar system is installed and HandlingTech becomes the official partner of the Stuttgart Kickers. Social commitment for children from Chernobyl.

Assembly area: 2,800 m2

Employees: 60

Sales: EUR 10 million

Number of sold robot cells: 500

Relocation to Steinenbronn

Move into the new production facility in Steinenbronn.

Development of an innovative robot cell, which practically loads your machining system “around the corner”, is advanced. The ecoZ concept is finalized at the end of the year.

A merger is completed with Waldmann & Weigl GmbH and eromobil is installed as a separate product line at HT.

Assembly area: 2,200 m2

Employees: 50

More space for new ideas

New construction begin in Steinenbronn, which advances at a record-breaking speed.

HandlingTech is honored with the FANUC Award for special achievements in the field of automation.

ROBAX receives a design award

The NewDesign ROBAX cell is awarded the iF product design award for innovative design.

Sales increases by 70% in this year.

However, the space in Möhringen is no longer large enough to cope with the rapid growth after the financial crisis was successfully overcome. Planning of a new building in Steinenbronn with double the capacity is now resumed.

Design of the ROBAX Cell in modular form for production lines using rail or top-mount-solutions.

Education partnership with the secondary school in Möhringen is initiated.

Assembly area: 1,200 m2

Employees: 33

Sales: EUR 7.7 million

Number of sold robot cells: 300

NewDesign for the ROBAX cell

Because of the drop in orders during the course of the economic crisis in 2008/2009, the company ventures down new roads. In cooperation with an industrial designer, a practical and extraordinary cell format is developed for the cost effective ROBAX cell. With the NewDesign ROBAX cell, HandlingTech emerges strengthened from the crisis.

Continued growth

The office space requires urgent expansion as a result of the consistent growth in Administration and Engineering.

First apprenticeship position in the technical division.

Assembly area: 1,200 m2

Employees: 17

Sales: EUR 6.5 million

Number of sold robot cells: 150

Takeover of Waldmann & Weigl GmbH

Waldmann & Weigl with its eromobil® eroding unit is exclusively taken over. At the same time, the conveyor belt sector is expanded into a separate department.

10-year anniversary celebration

HandlingTech celebrates its 10-year anniversary. Within a decade, the “cellar kids” have become a company that has established a name for itself in the market.

Assembly area: 1,000 m2

Employees: 10

Sales: EUR 4 million

Number of sold robot cells: 50

First step in robot automation

ROBAX, the first industrial robot solution, is introduced to the market. FANUC is found as a partner and the range of products is expanded to include articulated robots. Solar cells are installed on the company building.

Assembly area: 900 m2

Employees: 8

Sales: EUR 2.2 million

Move into the company headquarters in Stuttgart Möhringen.

HandlingTech automation solutions start to become more complex and larger. The assembly area used in the past is no longer large enough. Move into the facilities in the company headquarters in Stuttgart Möhringen.

Best prospects for success

Introduction of the PORTAX linear portal solution (today referred to as lineX) for loading and unloading machining systems.

A 3D CAD system is introduced and more complex customer requirements can be better implemented.

The production space has to be expanded.

Prestigious customers from the automotive industry as well as machine manufacturers and distributors are acquired as customers.

Assembly area: 300 m2

Employees: 7

Sales: EUR 1.8 million

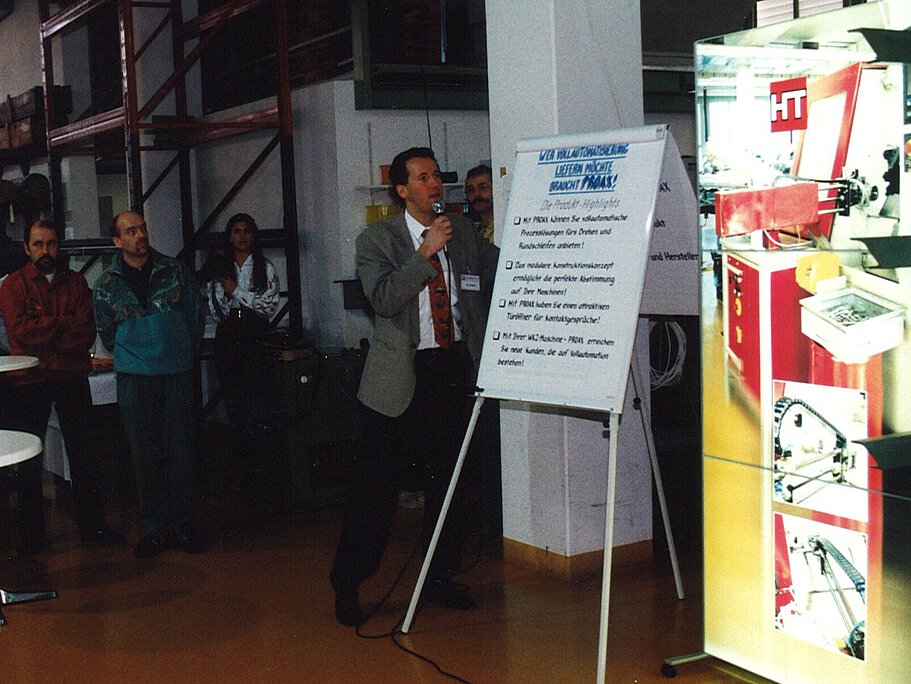

Hour of birth of the In-House Show

To celebrate HandlingTech Automations-Systeme GmbH’s fifth anniversary, the first in-house show takes place in the company’s new facility. This marks the hour of birth of the In-House Show.

Assembly area: 100 m2

Employees: 7

Sales: DM 1 million

First expansion of space

The first expansion of the administrative offices occurs in 1997. HandlingTech moves into the first floor of the company next door.

Foundation - Automation starts

With his diploma fresh in hand, engineer Jörg Hutzel, his brother Jochen Hutzel, managing directior of Hutzel DrehTech and Bernd Vollmer bravely took the first step in the field of automation. The first product of the company’s portfolio, a pneumatically driven linear loading unit for lathes, is given the name PROAX.

Sponsoring the Hutzel Racing Team.

Because the single device is being produced in the basement of Hutzel DrehTech in Steinbronn, the HandlingTech employees are often referred to internally as the “cellar kids”.

Assembly area: 70 m2

Employees: 3