Advantages

Intuitive operating concept.

Operate your systems intuitively via touchscreen and create added value through additional functions and networking. With the help of the HaTPad, you can configure workpieces and processes yourself according to your needs, thus minimizing your set-up and familiarization times. Central access to all operationally relevant data facilitates continuous optimization.

Features

More than just standard.

The cross-platform HaTPad offers a uniform user experience for all robot cells. Thanks to the structured and individually configurable user interface, you always have an overview of your ongoing processes. Your staff benefits from short training times and a minimal familiarization period. Even when using different robot brands, the user interface remains acquainted and understandable.

NOTE: The devices and screenshots shown are sample configurations and applications that can be adapted in many ways to your own needs. If you have any further wishes or requirements, please contact us. We would be happy to develop an individual concept and offer for you. ► Send project request

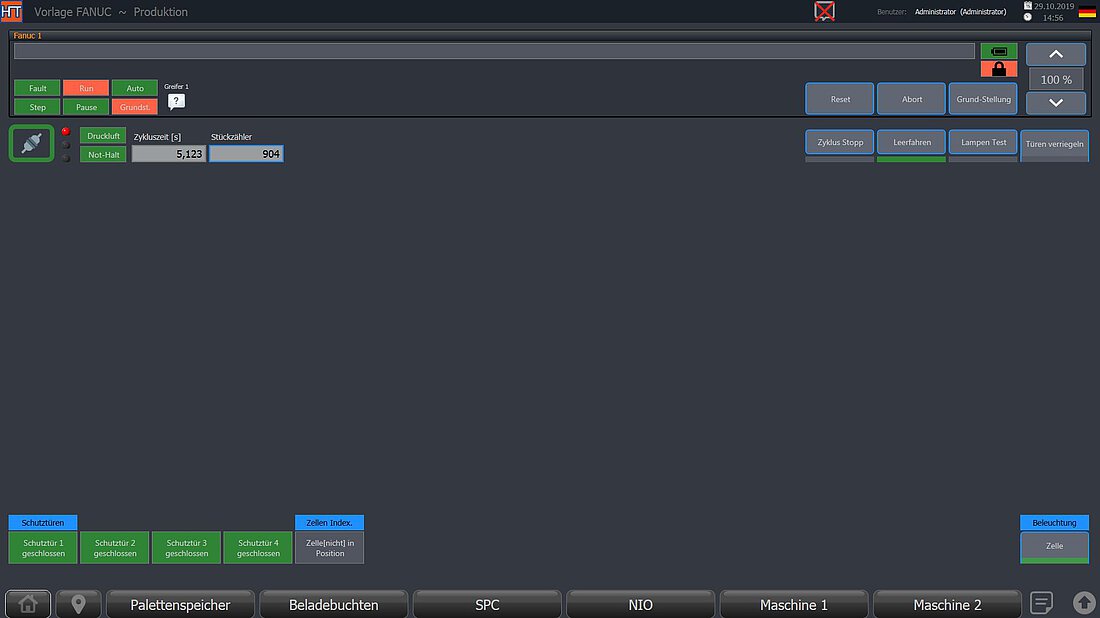

Control your system intuitively via the HaTPad. The universal user interface can be flexibly adapted to your individual needs. With Cell Messenger and Logger you are also informed about the current system status at all times.

Functions

- Clear system control

- Machine data visualization

- Cell Messenger

- Logger

- Preparation checklist

- Extended home position run

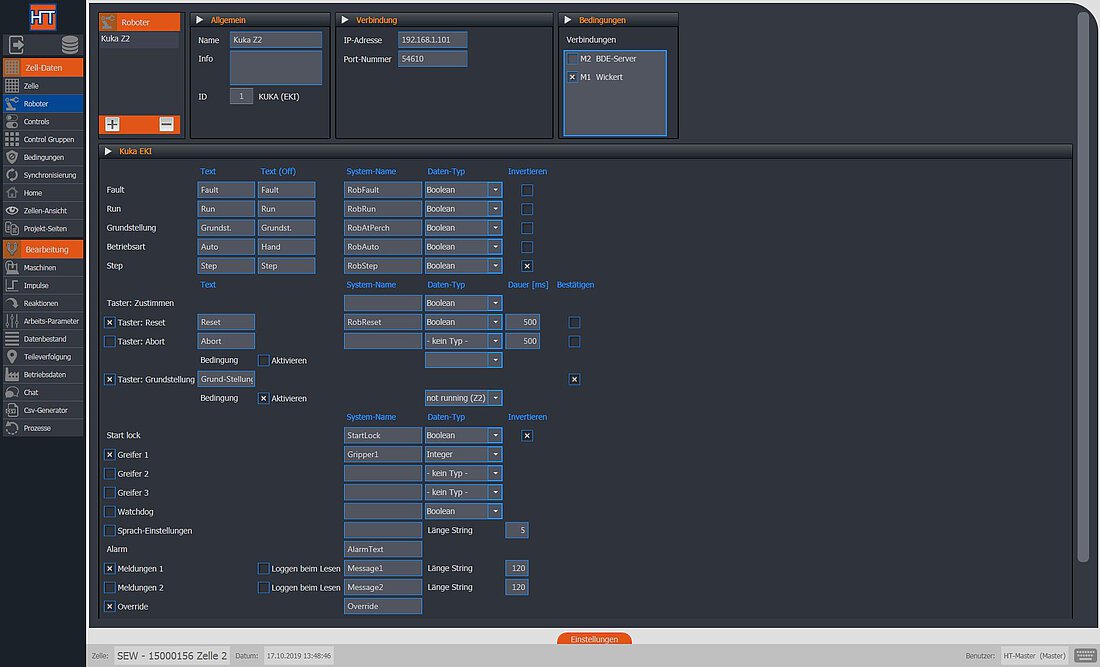

The PadStyler enables the extensive configuration of your HaTPad and the processes to be controlled with it. Assign corresponding processes to your range of parts and simply save them for quick retrieval.

Functions

- Configure interfaces

- Configure PadCockpit

- Configure processes

- Manage configurations

The Application Manager is your entry point into the world of the HaTPad. Start the apps you need at the push of a button, manage the authorizations of all users or take a look at the documents you have stored.

Functions

- Application manager

- Manage users

- Create backups

- Document library

- Cleaning mode

With the help of the remote maintenance tool, a large number of possible problems can be diagnosed and even rectified before a service technician arrives. An investment that pays for itself quickly.

To a certain extent, you can also install other applications you need on the Windows-based HaTPad. This makes the HaTPad an even more powerful control center for your processes.

Manage all workpieces, workpiece carriers, grippers and devices for the automation of your non-sorted production. Think, for example, of handling RFID-tagged pallets or workpieces with a data matrix code. The robot automatically recognizes the respective workpiece type and independently follows the associated sequence through to the selection of the appropriate machine program.

Record your operating data in the robot cell and make it available as an export file (CSV) or via an OPC UA interface for further processing.

You can seamlessly track all handled parts (tracing) including measurement data management for logging your relevant process data. Output as CSV file or via OPC UA interface.

The roboChat module enables data exchange (tracing, observation points, etc.) between several HaTPads. This is particularly useful if the system cannot be controlled from a central point due to its size.

| Touchscreen size | 17" - more sizes on request |

|---|---|

| Available languages | German - English - French - Czech - Polish - Romanian - Dutch - Chinese - more on request |

| Operating system | Microsoft Windows 10 LTSC |

| Compatible platforms | ecoZ - SRZ - palletZ - IRZ |

| Compatible robots | FANUC - KUKA - Stäubli - YASKAWA MOTOMAN - more on request |

| Network connection | LAN + WLAN |

| Remote access service | TeamViewer - more on request |

Variable platforms

Our storage and process modules can be integrated easilyand flexibly in our automation platforms. Find out which solution best meets your needs.

Infinite Service

Even after the purchase of your new system is complete, you can rest assured we will continue to support you. Our Service Team is here to help any time if you have questions or problems.

We are happy to consult you

Let us know the challenges you face in your production. We work with you to provide the right solutions and take care that they are implemented.